Our customers feedback

DB Breweries is one of the most well-known companies in New Zealand. Originating in 1929, the business now has a team of over 500 across the country. Crowcon was initially asked to provide a quotation to DB Breweries by the company’s health and safety advisors, a trend which is increasing within the food & beverage industry as the industry is currently upgrading its gas detection policies.

The Requirement

Along with the New Zealand Government’s initiative to reduce workplace accidents in the manufacturing sector, is driving demand for a gas detection solution with food and beverage as it proactively addresses the potentially catastrophic outcomes of workers becoming exposed to dangerous levels of CO2 gases.

Many do not fully appreciate that CO2 is toxic. This is possibly because it occurs naturally in the atmosphere, albeit at very low concentrations – around 400 parts per million (ppm). It is used or produced in the brewing and pub industry both during production and in the bar or restaurant, and we even produce it when we breathe out. We breathe CO2 out because it is toxic, of course, and great care is needed when working in environments where it may be present at elevated levels.

Approach

Brewery industry employees who enter drinks storage areas without adequate gas monitoring equipment are potentially entering a life-threatening environment. If workers are equipped with personal monitors before they enter a risk zone, gas levels can be monitored. In this case, Crowcon’s single-gas Gasman CO2 IR was selected largely due to its infrared sensors. Infrared sensors tend to have a faster response time and longer active life than other CO2 sensor technologies, as well as performing better at the lower temperatures that can be encountered in cellars. As part of the gas detection solution, service and calibration of instruments is provided.

CO2 is heavier than air. It is a hazard throughout the manufacturing process, right through to packaging and bottling, and even to the bars and eating establishments where the drinks are served. If CO2 escapes, it will tend to sink to the floor, where it can form deadly, invisible pockets. It collects in cellars and at the bottom of containers and confined spaces, such as tanks and silos.

Outcome and Benefits

DB Breweries Hamish Clentworth, explains: “One of the key factors in selecting Crowcon was the flexibility of its device. The ability to select the alarm function to best suit the working conditions whilst ensuring safety, is paramount, as it ensured minimal disruption when our sales teams visited bars, restaurants or retail outlets. Furthermore, the response time when increased CO2 levels are present was impressive, which meant our employees are alerted of the possibility high levels of CO2 in good time.

Even when gas detectors are deployed; maintaining protection for every employee can be a challenge as CO2 can be present in several areas; gas detection devices must be an integral part of an employee’s daily routine.

Hamish Clentworth

DB Breweries

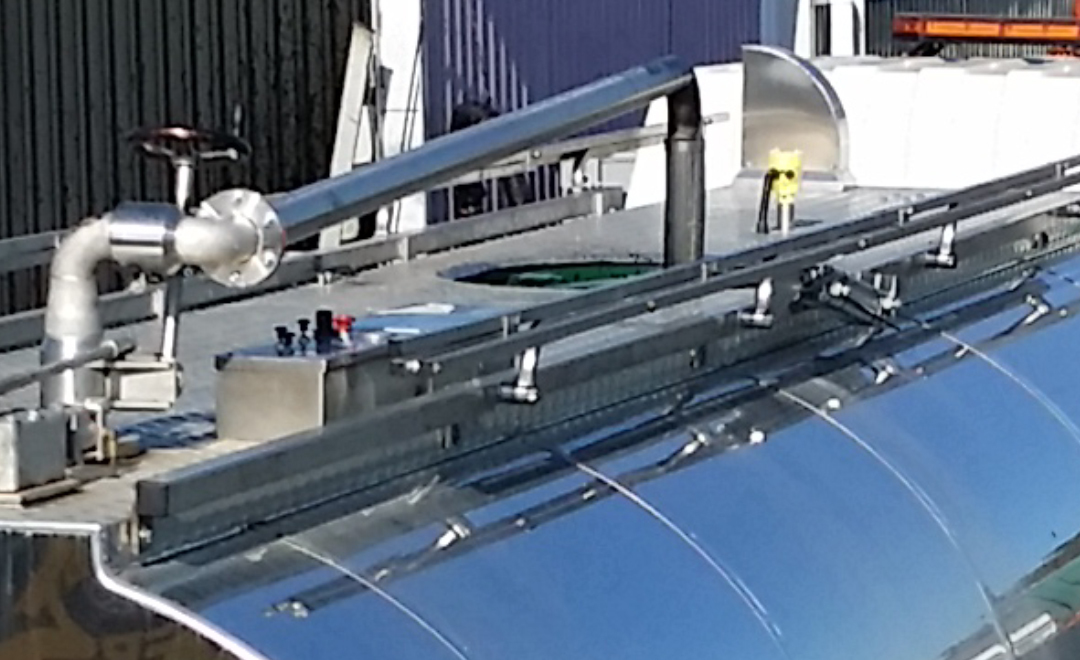

Penny Engineering build bitumen tankers and sprayers for customers throughout New Zealand. Each Penny Sprayer is custom-built to individual customer requirements, ranging from 2,000L to 12,000L capacity. Penny Sprayers are constructed by a team of skilled craftsmen based in Palmerston North, using materials suitable for the robust nature of the bitumen industry. Penny Engineering also manufactures bulk bitumen trailers from single axle trailers to quad-axle semi-trailers.

It's not uncommon for Penny Sprayers to go for 20 years without a refit.

When designing the trucks, it was imperative that continuous level information be directed to the operator, to ensure the most efficient use of bitumen to be supplied to spray units and to avoid running tankers below safe operating levels. The high operating temperature and complex internal structure dictated the need for instrumentation with a rugged structure and beam angle that was unaffected by unique tank size, baffles and ladders. the continuous change in temperature of bitumen leads to high build-up on the internal surfaces within tankers, including build-up on internal sensors. The right instrument could ensure not only efficient operation, but also worker safety through automated tanker operation.

The Vega PULS64 offered all of the above demanding specifications, in addition to easy setup, huge range of process fitting options and long sensor life.

Use of the PULS64 has led to purchase of other level instrumentation from Instrumatics: Capacitive Vega CAP63 over-ride switch in tankers; VEGA-Wave switches for use in fixed silos containing concrete and signal conditioners for local displays and easy setup.

Penny Engineering will continue to use VEGA products for the design and manufacture of bitumen and concrete vessels. The service received from Instrumatics has more than met our expectations. Not only do we receive the correct instrument with on-time delivery, but staff are friendly and efficient.

For more company information about Penny Engineering, click here.

Craig McKechnie

Penny Engineering, Palmerston North